Design and production of critical components and complex pharmaceutical product contact systems for filling, packaging, and pharmaceutical machines.

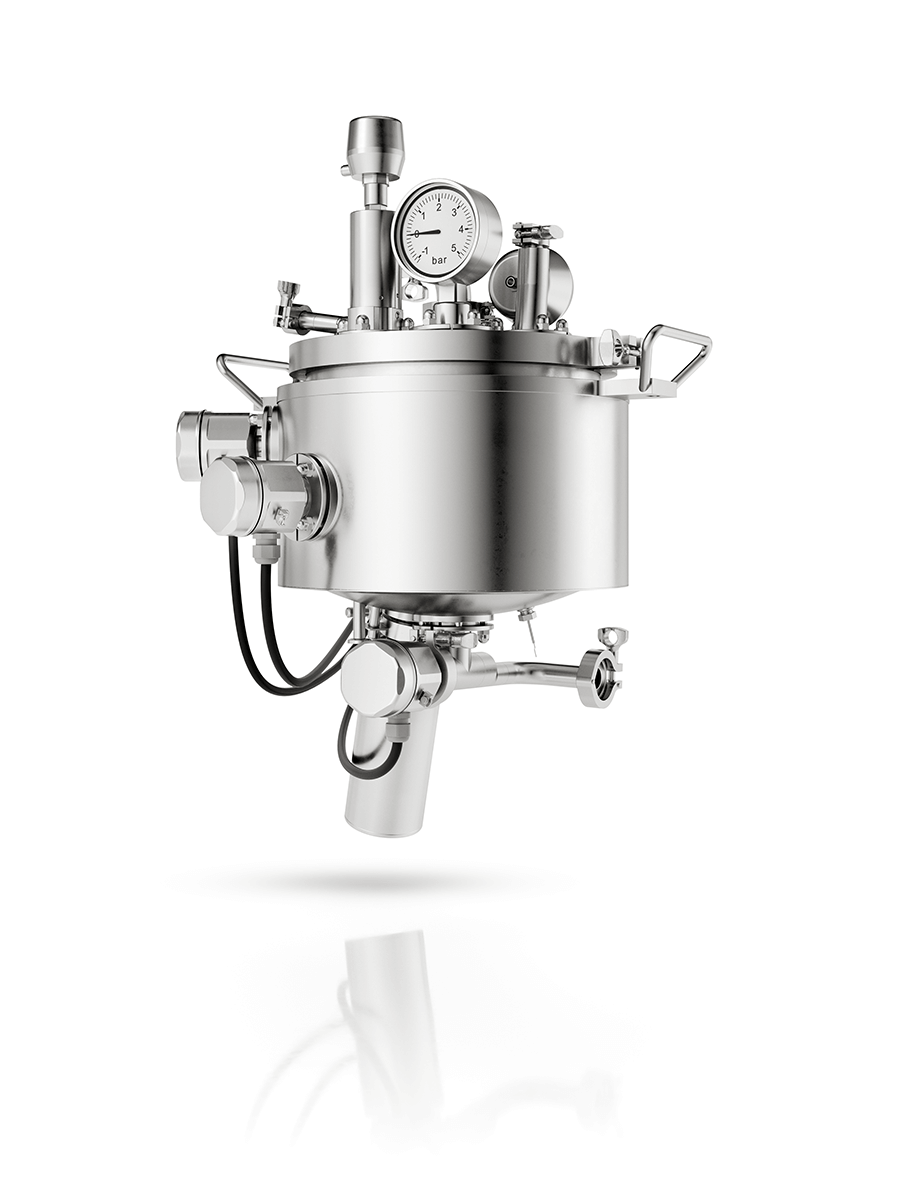

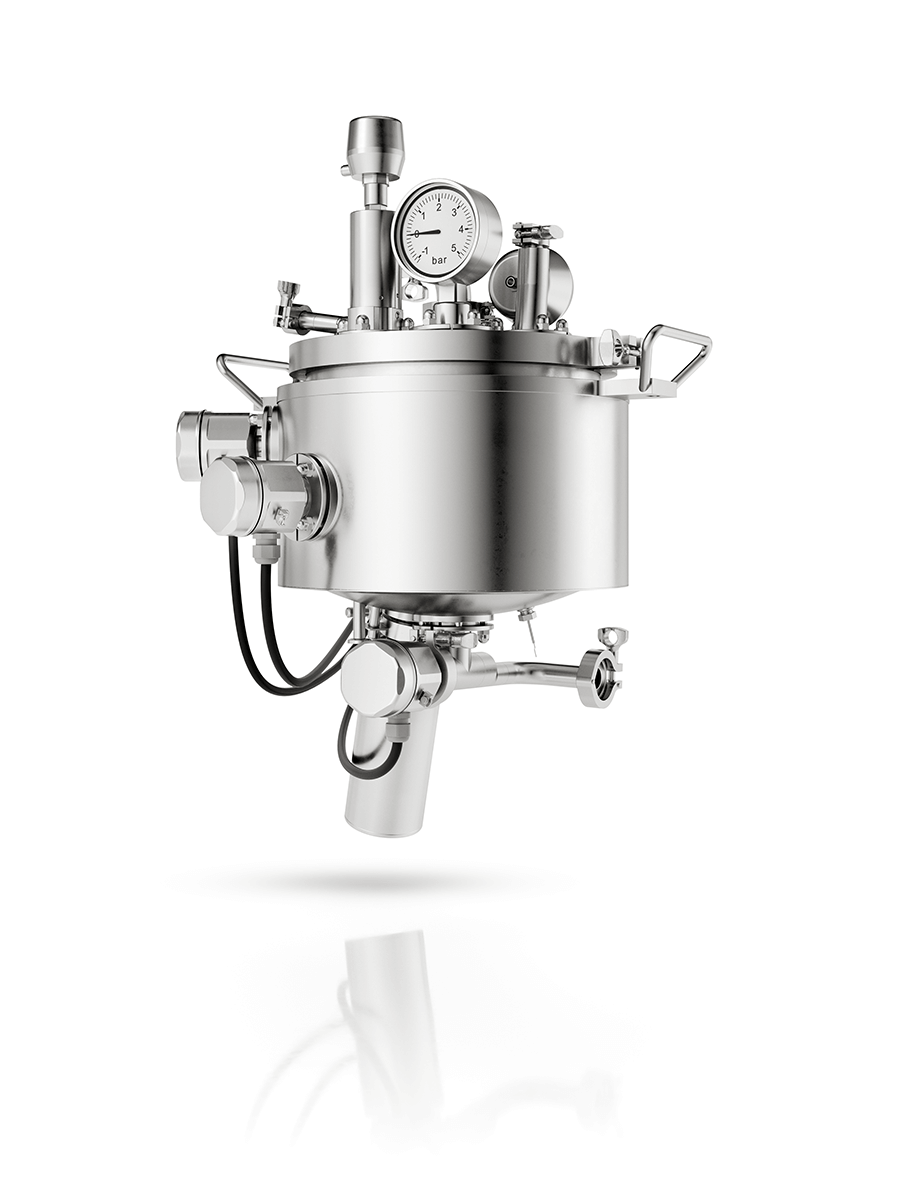

Custom tanks

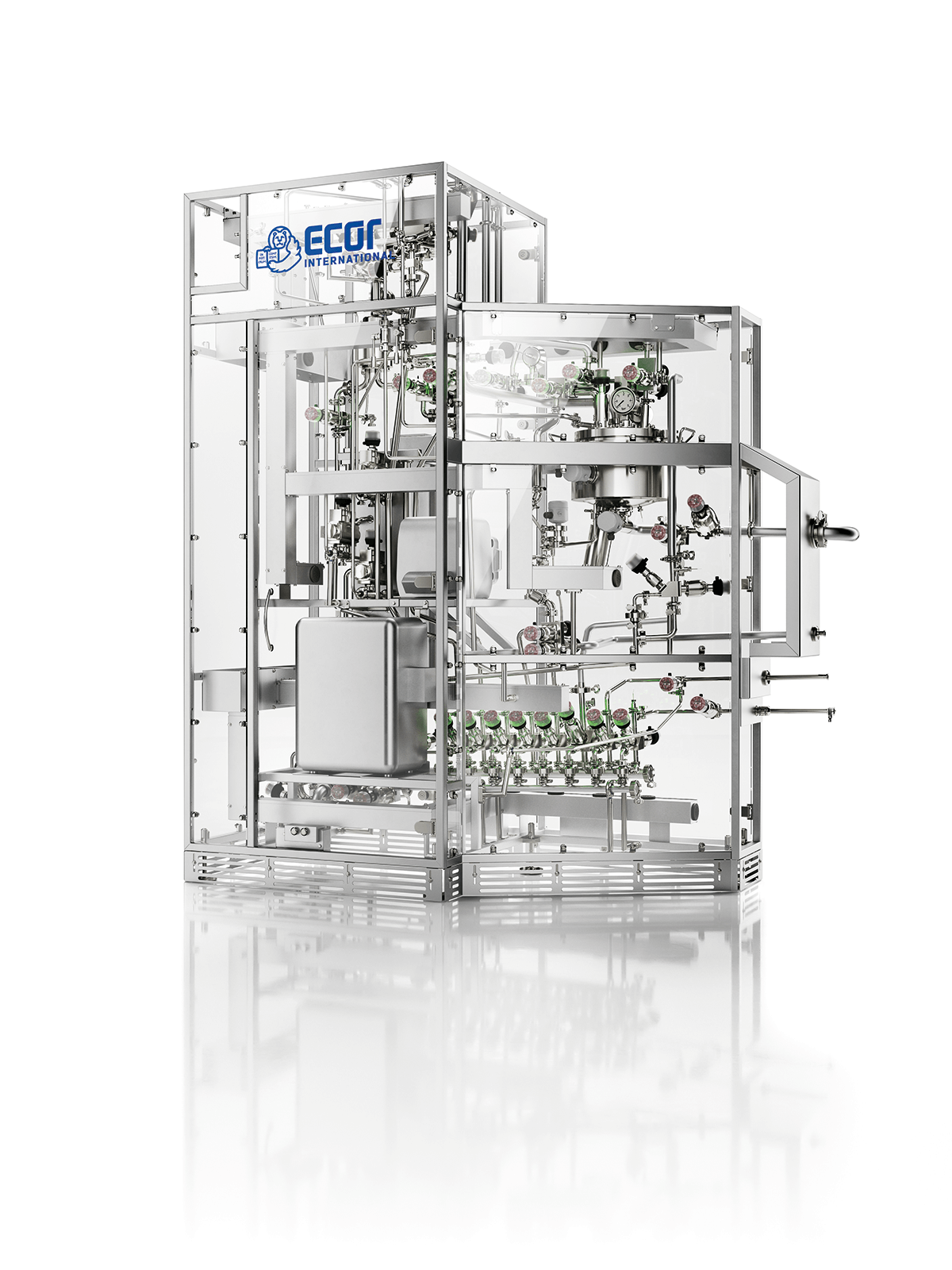

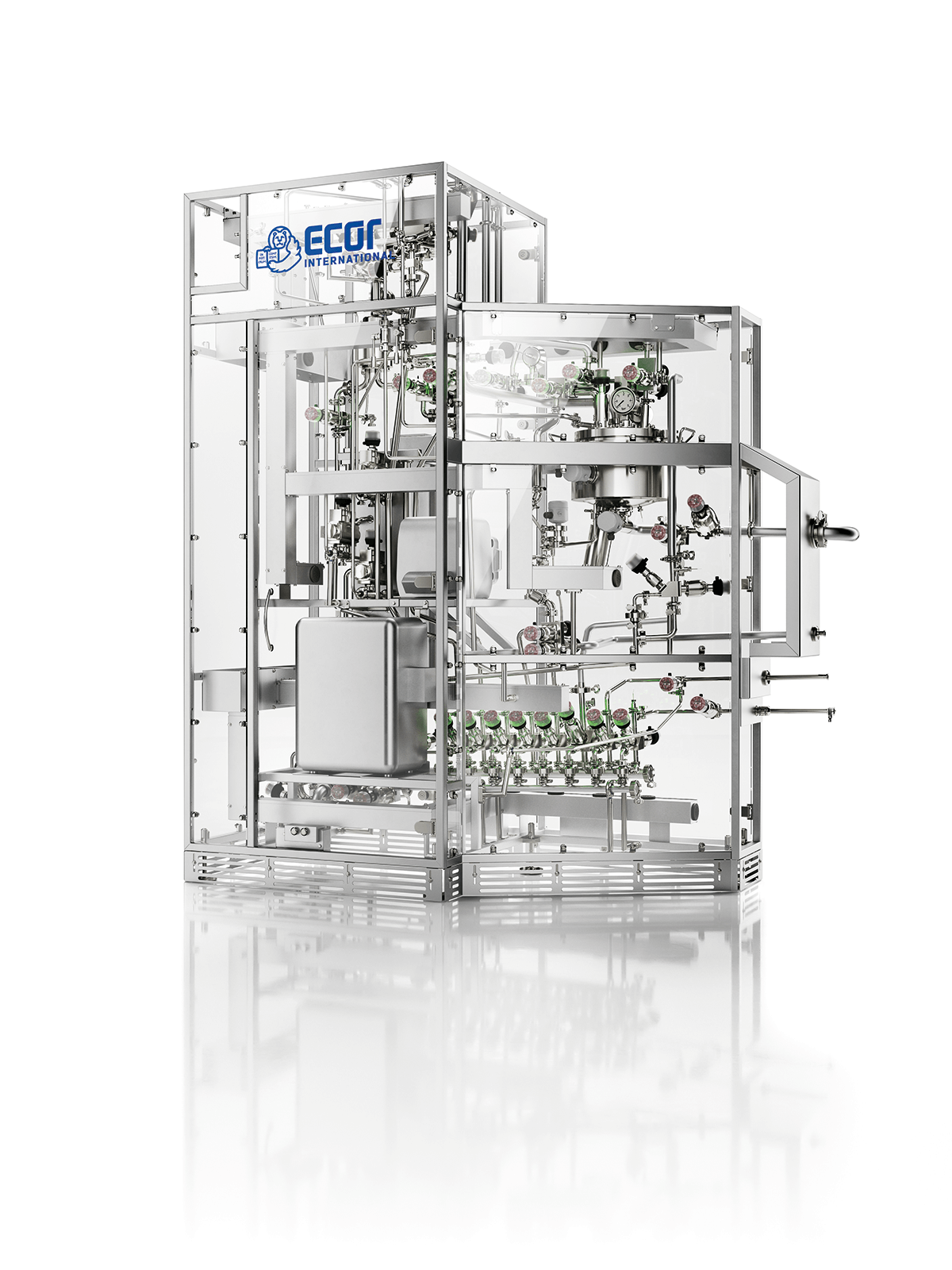

Process & biotech solutions

PRODUCTS

Design and production of critical components and complex pharmaceutical product contact systems for filling, packaging, and pharmaceutical machines.