Innovative hi-tech solutions

for all sectors

Within the Advanced Mechanics Business Area, we supply our customers with hi-tech solutions, components and critical systems. In particular, we make critical components and complex systems from stainless steel and special alloys, braze complex units and assemble electro-mechanical sub-assemblies.

The transferable skills and technology in our production plants enable us to operate in a wide range of industrial fields.

We offer our services to companies in the pharmaceutical industry, companies that assemble systems and subsystems, research centres and universities that require comprehensive support in order to improve the performance of machines and systems and optimize production processes.

COMPONENTS

We produce critical components and complex systems made of stainless steel and special alloys for automatic machines, vacuum systems:

- Critical piping for process fluids

- Pressurised vessels

- Stainless steel panels and roofing

- Washing and sterilisation systems

- Complex welded units

- Assembled complex units

- Brazed complex assemblies

BUSINESS AREA OVERVIEW

Activities

- Design, prototyping and validation of critical components and complex systems

- Production of drawn critical components and complex systems in steel and special alloys

- Brazing of complex assemblies

- Assembly of electromechanical subassemblies

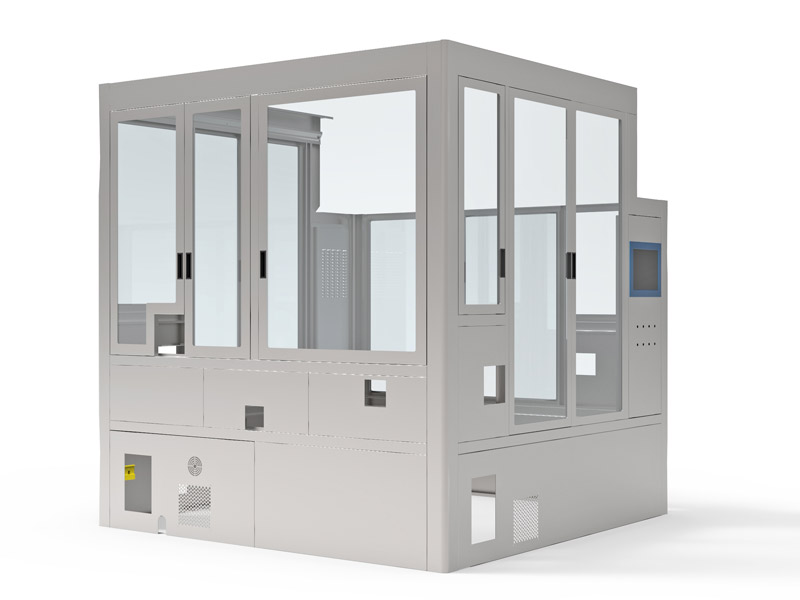

- Design and production of mobile water purification units and Pass Box Systems

Products and Components

- Critical piping for process fluids

- Pressurised vessels

- Stainless steel panels and roofing

- Washing and sterilisation systems

- Complex welded units

- Assembled complex units

- Brazed complex assemblies

- Mobile water purification units

- Pass Box Systems

Intended use of components

- Pharmaceutical processing and packaging systems

- Vacuum systems

- Hospital furnishing

Clients

- Manufacturers of pharmaceutical packaging systems

- Manufacturers of vacuum systems

- Companies that assemble medium-to-highly complex systems and subsystems

- Research Centres and Universities

Distinctive features

- High-tech solutions

Markets

We work in a number of specific market areas: machines for the pharmaceutical industry, high vacuum products and experimental equipment for particle physics. In addition, thanks to the transferable skills and technology at our disposal, we are able to offer our services to a broader range of companies that assemble systems and subsystems of medium to high complexity.

For experimental equipment

In the field of experimental equipment for particle physics, we produce mechanical assemblies and provide for the subsequent brazing of components for experiments in stainless steel, copper, ceramics and other alloys. Its key customers include some of the most important Research Centres and Universities in Italy and Europe.

For machines in the pharmaceutical industry

Piping for product flow, complex collectors, tanks and complete CIP – SIP (Cleaning In Place – Sterilisation In Place) modules that perform cleaning and sterilisation cycles are the main products used for machines in the pharmaceutical industry. They are highly complex components and complete systems for which mechanical, electrical and pneumatic know-how is required. These products have always distinguished themselves for their dimensional tolerances and high surface roughness. In addition to producing and assembling components, we support customers in design or consulting to improve system performance.

For high-vacuum products

We produce ion pump components for the high-vacuum product sector. The components are stainless steel units (laser welded or TIG welded) or brazed components. In both cases they are critical units given the required tolerances, vacuum demands, dimensional consistency, difficulties encountered during assembly and the need to keep the surfaces clean (no contamination). The checks throughout the processing phases are very strict and provide for the use of state-of-the-art instruments and highly qualified personnel.

TECHNOLOGIES

We use manual, automatic and robot TIG welding and automatic laser welding technologies, and process piping and sheet metal with CNC machines. We use high-vacuum brazing and heat and surface treatments (pickling, passivation, electropolishing and thermal spraying) to improve the performance of components.

Engineering

We employ a team of 25 mechanical, mechatronic and materials engineers and designers who, in close contact with clients, are engaged in mechanical engineering, electrical engineering, pneumatic design, structural, fluid and thermodynamic certification, and hardware and software design activities, as well as in the issue of technical publications and CE declarations.

Certifications

The quality management system and the focus on health, safety and the environment are a core part of our corporate culture. Our efforts in this area are underlined by the Quality Management (ISO 9001), Health and Safety (OHSAS 18001) and Environmental Management (ISO 14001) certification that we have been awarded over the years. In addition, we have received a range of accolades from customers and ASME BPE certification for our welding processes.

Business Manager Advanced Mechanics

Ing. Fabio Pozzebon