What we excel at in Ecor International

Our distinctive features enable us to create reliable products with high criticality of use and complexity in realization.

STAINLESS STEEL

SPECIAL ALLOYS: NICKEL AND TITANIUM

ALUMINIUM

Technologies: We carry out both automatic and manual welding using:

● laser welding

● MIG welding

● TIG welding

● Automatic welding

● Manual welding

● Resistance welding (spot and seam)

We carry out non-destructive tests such as:

● X-rays (film and digital)

● Fluorescent penetrant testing

● Helium and impression testing

We carry out galvanic treatments:

● Pickling

● Electropolishing

● Passivation

METAL-CERAMIC JOINING

Technologies:

● High vacuum furnace (TAV)

CUTTING, BENDING, AND SURFACE FINISHING OF PIPES AND SHEET METAL

Technologies: We carry out both automatic and manual welding using:

● tube and pipe benders

● laser cutting

● crimping

Skills and expertise of the Research Centre

Our Industrial Research Centre, the Il Sentiero International Campus, researches materials, surfaces and processes to tackle the challenge of innovation.

We study the behaviour of materials, components, and systems in certain states and time periods.

We develop process-product systems to make a surface suitable for a specific application.

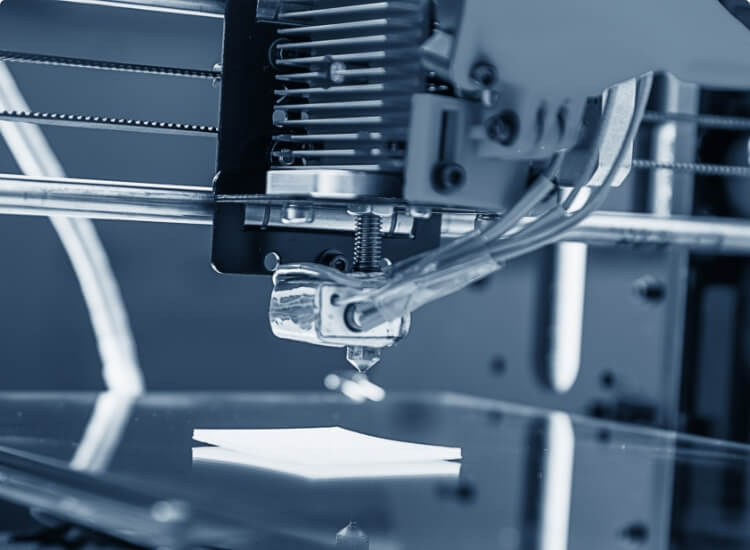

We optimise and develop process-product systems for the Additive Manufacturing sector.

We study, design and develop machines, plant systems and prototypes for different sectors.