A STORY OF IDEAS AND COURAGE SINCE 1976

1976 | Launch of Ecor

Sergio Lucietto opened an office under the name Ecor in the centre of Schio, near Vicenza. It provided stainless steel trading services for small businesses in the local region. The name “Ecor” is an acronym of “Ecology” and “Research”.

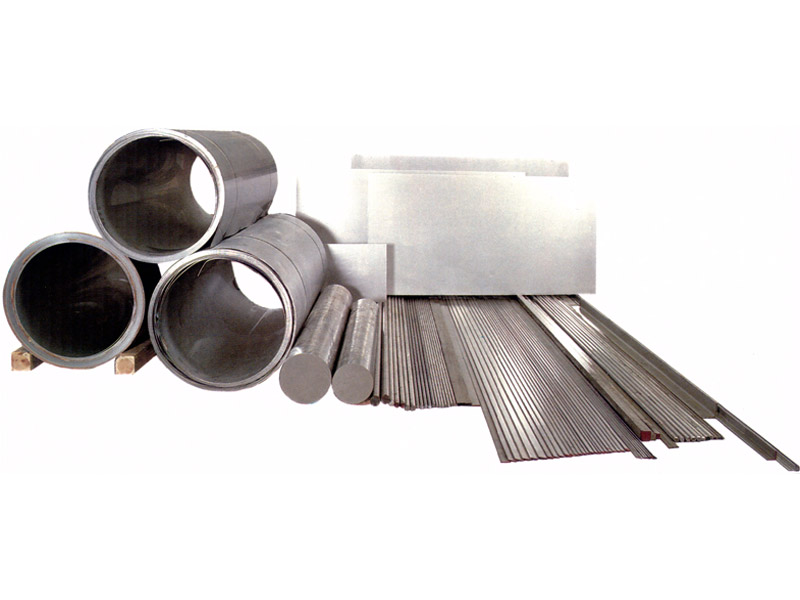

1979 | The first warehouse

The volume of business increased and Ecor needed better storage facilities for its larger materials, such as pipes and bars. Therefore, it rented part of a garage in the Schio industrial estate.

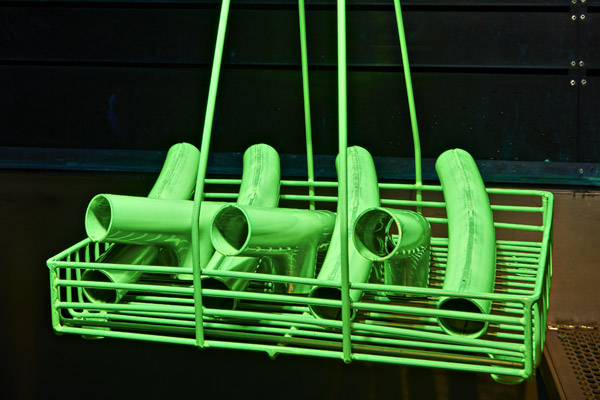

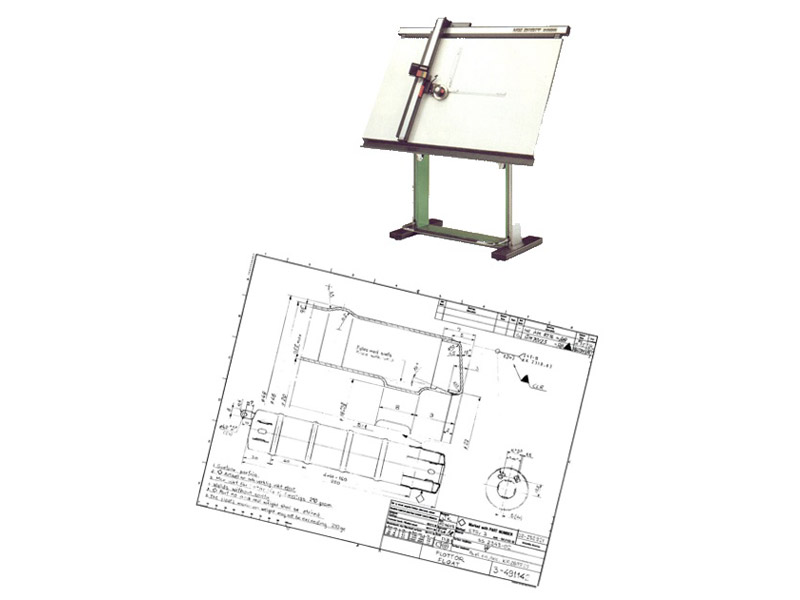

Creation of a mechanical processing department

The business began to diversify: a mechanical processing department making products to design was created in a section of the warehouse. A metal engineering workshop with vast expertise of welding and specialist procedures gradually took shape.

1981 | The first company-owned premises

Customer demand kept growing and Ecor needed larger production facilities. The first company-owned production plant was built at 9 Via Friuli and all of the industrial activities were transferred there. The site was subsequently extended to a size of 5,000 m².

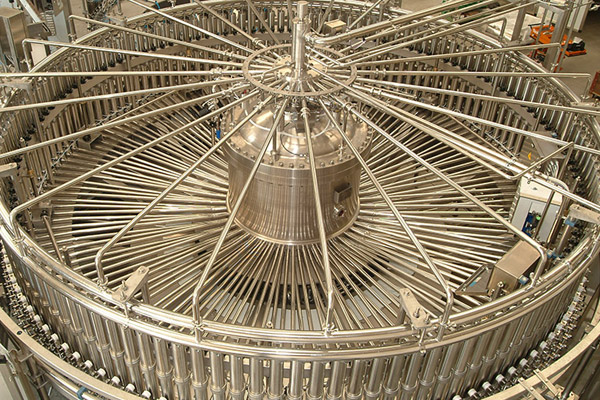

1982 | Debut in the packaging market

The company moved into the field of automatic food processing and packaging machines when it started making highly critical welded components for the Swedish multinational Tetra Pak, which had decided to invest in Italy and was looking for new suppliers at the time.

1989 | Group expansion

Euro Inox Quality, a Schio-based manufacturer of stainless steel enclosures, joined the group. Ecor now owns 100% of the company, which has focused on the production of EiQ Industrial-branded electric panels since 2014.

1998 | Quality certification

The company was awarded ISO 9001 Quality Management System certification.

1999 | Production site expansion

A new plant was opened at 11 Via Friuli in Schio, next to the existing premises. Including outdoor areas, the total industrial surface area covered is 16,000 m².

2002 | The group continues to establish itself

There was another addition to the group in the form of NPC (New Production Concept),

an Imola-based company that produces and assembles units for the food industry.

Ecor now has a 40% stake in the business.

2004 | Environmental certification

The company was awarded ISO 14001 Environmental Management System certification.

2009 | Launch of Ecor Research

Following a proportional demerger, “Ecor” changed its name to “Ecor Research”

and took charge of critical component design and production activities,

as well as the stakes in companies.

Diversification into the aerospace market

The company entered the Aerospace and Defense industry, becoming a supplier of critical, functional and structural components installed in civil and military aircraft. It began the process of working towards the certificates required to operate in a market with substantial barriers to entry. The first project involved the production of a number of titanium alloy parts to prevent galvanic corrosion in Boeing 787s.

2010 | Debut in Reliability Engineering

With the introduction of the first test rig to check corrosion of a component with hydrogen peroxide, a functional testing service was launched. Using test rigs with machinery that was designed and built in-house, components, systems and subsystems of automatic machines were tested to assess their life cycles and reliability.

Aerospace Quality Management Certification

The company was awarded AS/EN 9100 Aerospace Industry Quality Management certification, which is a key prerequisite for operating in the market today.

2011 | Welding and Heat Treating Accreditation

The company was awarded NADCAP accreditation for welding and heat treating processes in the aerospace industry.

2013 | Health and Safety Certification

The company was awarded OHSAS 18001 occupational health and safety certification.

2014 | Joining POEMA

With an investment of €2,450,000, Ecor Research joined the POEMA (European Centre for Aerospace Precision Casting) network of 12 companies, which aims to improve the performance and efficiency of aircraft engines and turbine components.

Accreditation for Non Destructive Testing

The company was awarded NADCAP accreditation for nondestructive testing.