From energy to biochemistry with a single objective: ensuring safety and quality

The Business Life Science and Green Energy area is responsible for designing and manufacturing components dedicated to sectors such as energy, semiconductors and pure fluids, vacuum pumps, air treatment and air conditioning, chemical, biochemical and research.

The transversal skills and technologies deriving from the experience gained within the Food Industry allow us to create systems and subsystems with medium-high complexity and technologically advanced.

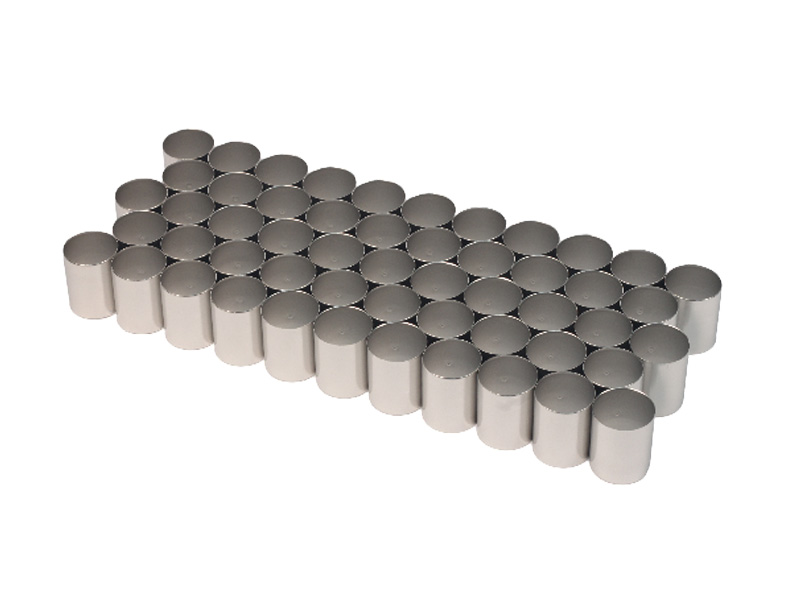

COMPONENTS

BUSINESS AREA OVERVIEW

Activities

- Design, prototyping and validation of critical components and complex systems

- Production of critical components and complex design systems in steel, special alloys and ceramic materials

- Brazing of complex assemblies of steel, special alloys and ceramic materials

Products and components

- Critical components in stainless steel, special alloys and ceramic materials

- Electrical Feed-through

- Components and systems for vacuum and ultra-vacuum applications.

- Components and systems with high particulate cleaning standards.

Intended use of products and components

- Vacuum systems

- Co-generation and renewable energy systems

- Customized solutions for the research sector

- Chemical industry installations

- Air treatment plants

- Life science machines and instruments

- High purity fluids production plant and machine

- Semiconductor plant and machine

Clients

- Companies producing vacuum equipment and products

- Companies producing systems or components for pure fluids

- Companies producing semiconductor plants or components

- Companies producing plants or components for Life Science

- Companies producing plants or components for cogeneration and renewable energy

- Companies assembling medium to high complexity systems and subsystems

- Research Centres and Universities

Distinctive features

- Tight dimensional tolerances

- High-tech solutions

- Production process reliability

- High standards of chemical and particulate cleaning

TECHNOLOGY

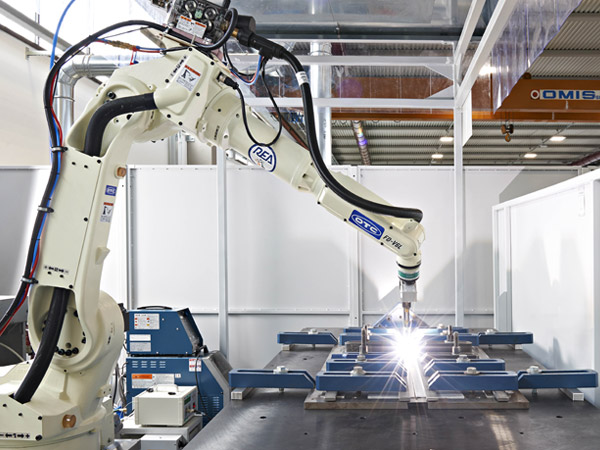

We use manual, automatic and robot TIG welding technologies, automatic and manual laser welding, complex tube and sheet metal machining with CNC machines.

We use high vacuum brazing and thermal and surface treatments (pickling, passivation, electropolishing and thermo-spraying) to improve the performance of the components.

REALIBILITY’

Reliability has been a key feature of Ecor International production for over 40 years. Designing and manufacturing of complex components for the energy, chemical and biochemical sector pushes us to provide the highest quality and safety.

CERTIFICATION

We received the NADCAP accreditation for welding processes, heat treatment and non-destructive testing. As part of a quality adjustment path to comply with industry standards, we are AS/EN 9100 certified for Aerospace Industry Quality Management.

In addition, we hold certifications on Quality (ISO 9001), Health and Safety (ISO 45001) and Environment (ISO 14001). Finally, leading national and international companies have qualified our production processes.

QUALITY

Being aware of the high criticality of our special processes, we certify the conformity of the components produced through in-house quality controls. In the production plants, specialized and qualified technicians perform non-destructive controls (radiographic and through dye penetrant inspection), dimensional controls (via Measuring Machine Coordinates and optical vision systems) and visual with video-endoscope.

MANAGEMENT

The production and management chain is structured according to the most modern methods, including Total Quality Management and World Class Manufacturing. In a perspective of continuous improvement of our activities, thanks to business objectives shared at all levels, special attention is payed to the optimization of costs and delivery